Proof of Concept: ERC-2017-PoC 779611

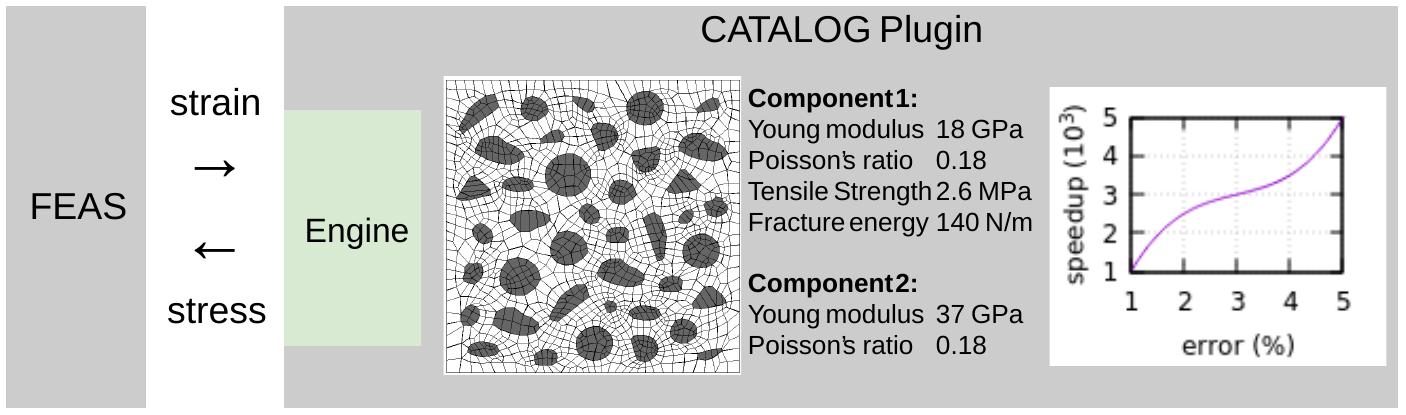

CATALOG explores the industrial applicability and potential for commercialization of a prototype of a “computational multiscale material catalog”, to exploit HPROM (high‐performance reduced order modeling), a technology developed in the ERC Advanced Grant COMP-DES-MAT for advanced material simulation. CATALOG will provide extremely fast and accurate multiscale capabilities to existing commercial Finite Element Analysis Solvers (FEAS), greatly enhancing their standard simulation performance. Implemented as a plugin, the coupling CATALOG‐FEAS will be completely noninvasive and adaptable to most commercial FEAS.

The efficient and accurate material multiscale simulation HPROM —core technology behind CATALOG— is capable of outperforming state-of-the-art solutions by 1000x in computational cost at same precision. Presented in a user-friendly portable format, our software will provide the user with a rich selection of validated multiscale material models with customizable accuracy-speedup. With CATALOG, industrial designers will have access to new simulation capabilities currently unavailable.

The fundamental technology of CATALOG includes the use of multiscale modeling , i.e. consideration of the structure and morphology of the material at two scales, where the complex topologies at the microscopic level govern the macroscale structural behavior. Both scales are linked by computational homogenization , a process based on finite element computations at the microscale , accounting for an accurate description of the material morphology and topology, no matter its complexity. Relevant features of CATALOG are:

● Implementation of the HPROM will overcome the challenge posed by the enormous computational cost associated to the true computational multiscale.

● Capability for efficient simulation of most material behaviors, including dissipation processes, complex loading/unloading trajectories, material localization and fracture, dynamic processes, among others.

● No limitation in the number, material behavior, nor strain range of the components at the microscale.

● Possibility of running multiple instances in parallel computing environments, allowing for extra reduction of computing time, on top of the reduction stated in this proposal.

● Incorporation of the concept of user-selected accuracy , at the expense of computing time.

● Its implementation as a plugin compatible with most modeling software facilitates technology adoption.