F Engines

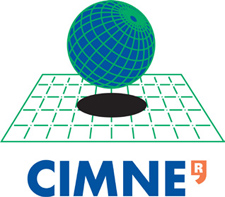

The blowing engine weighs 40 kg and fits well on a pallet of 1m². The air-ducts can be folded and stored in very litle space.

The blowing engine weighs 40 kg and fits well on a pallet of 1m². The air-ducts can be folded and stored in very litle space.

E Material

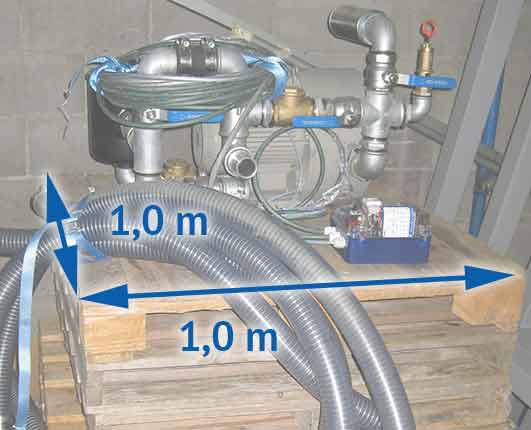

The sling and all the screws, couplings, shear transmission washers, metal, plates and tools fir into a box of 1,00m x 0,50m x 0,50m. The steel supports and anchoring plates measured as maximum of 2m.

The sling and all the screws, couplings, shear transmission washers, metal, plates and tools fir into a box of 1,00m x 0,50m x 0,50m. The steel supports and anchoring plates measured as maximum of 2m.

D Reduce volume when folded

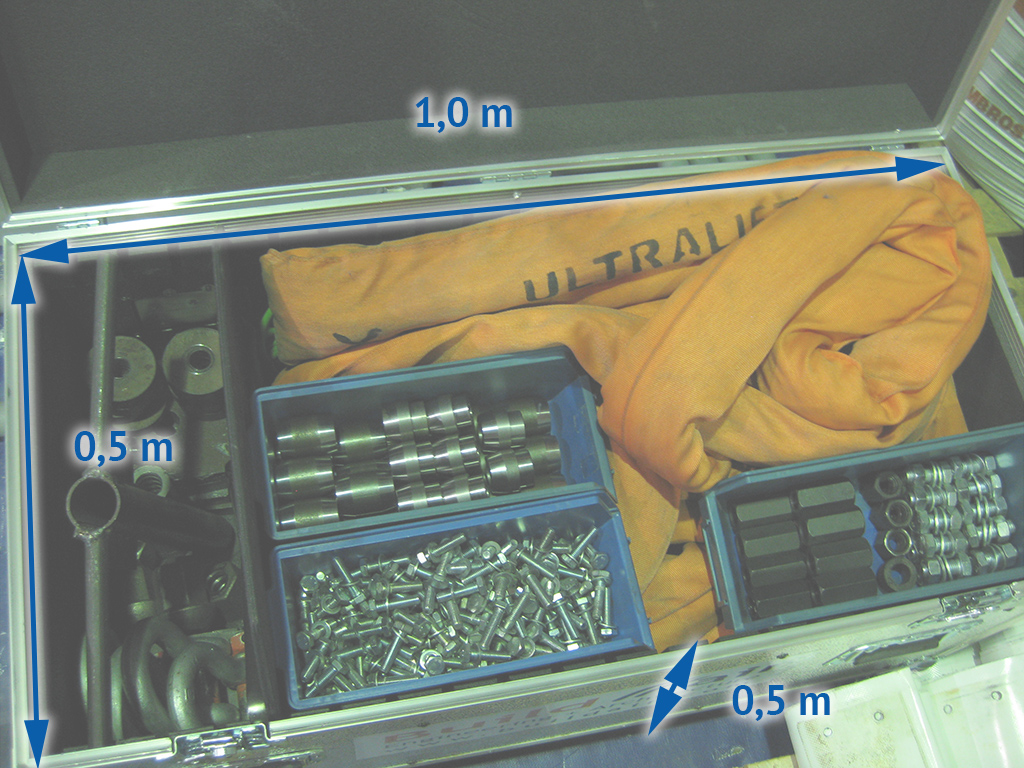

The inflatable tube of the air-beam occupies approximately 0,7 m ³, when folded, compared to the volume of 19 m³ when inflated.

The inflatable tube of the air-beam occupies approximately 0,7 m ³, when folded, compared to the volume of 19 m³ when inflated.

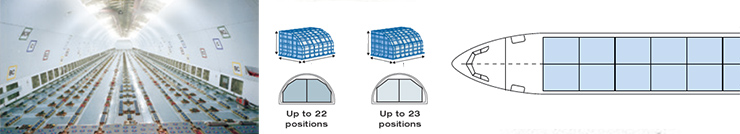

Transport

Since the bridge must be easily dismantled and portable, it is composed of pieces that fit into standard pallets of 88? x 54? for freight aircraft.

Since the bridge must be easily dismantled and portable, it is composed of pieces that fit into standard pallets of 88? x 54? for freight aircraft.

C Placement of the sling

With the tie bands fixed on the deck side, the sling is placed through the dowel pins designed for this purposed. After, everything is placed over the tube and the strips are fixed to the other side. Once it is fixed and the tube is semi-inflated, the sling is anchored to the ends of the beam.

With the tie bands fixed on the deck side, the sling is placed through the dowel pins designed for this purposed. After, everything is placed over the tube and the strips are fixed to the other side. Once it is fixed and the tube is semi-inflated, the sling is anchored to the ends of the beam.

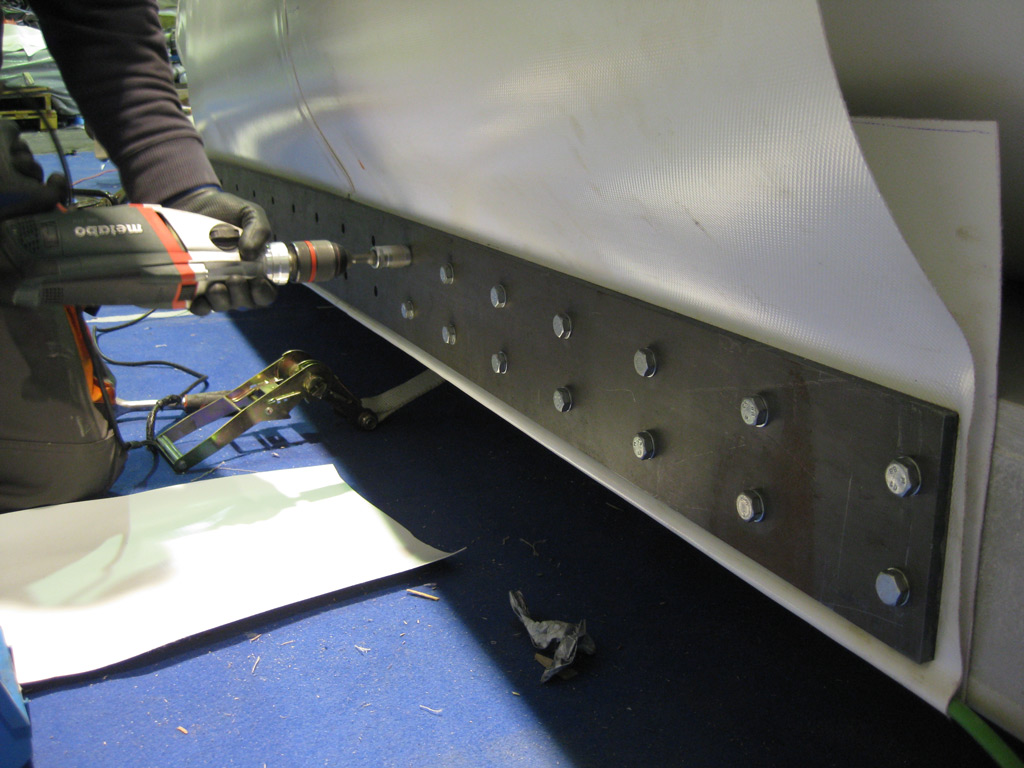

B Positioning of the tube and tie bands

The tube is extended and centered on the deck. Later on, tie bands are fixed to the side of the deck by using bolted steel plates. Joints between panels are also screwed.

The tube is extended and centered on the deck. Later on, tie bands are fixed to the side of the deck by using bolted steel plates. Joints between panels are also screwed.

A Deck assembly

The panels are aligned and the longitudinal steel bars are introduced thorugh the joint area, adding also the shear transmission washers. The longitudinal bars are joined with couplings into the holes provided for this purpose on the board. The steel supports are finally added to the ends and the rods are tightened by nuts, for prestressing.

The panels are aligned and the longitudinal steel bars are introduced thorugh the joint area, adding also the shear transmission washers. The longitudinal bars are joined with couplings into the holes provided for this purpose on the board. The steel supports are finally added to the ends and the rods are tightened by nuts, for prestressing.

Assembly

Unlike other fast-deployment bridges alternatives, the assembly of the Air-Bridge can be done easily in about eight hours with a team of eight workers. The process takes place in an inverted position on the ground; it is identical for the two beams and can be performed in parallel (except turning maneuver and positioning).

Unlike other fast-deployment bridges alternatives, the assembly of the Air-Bridge can be done easily in about eight hours with a team of eight workers. The process takes place in an inverted position on the ground; it is identical for the two beams and can be performed in parallel (except turning maneuver and positioning).